PROJECTS

Water/Waste Water

In this project, we installed a Micro850 PLC and HMI to manage a water loop system. The system incorporated floats and a level sensor to provide continuous monitoring of water levels, automating withdrawals from the tank when predefined levels were reached. To enhance operational visibility, we integrated a flow meter to measure water flow in real time and totalize daily water usage, providing critical data for improved system management.

We also managed the physical wiring and termination within the control panel, ensuring everything met industry standards for safety and reliability. From start to finish, our team expertly commissioned the system, testing and fine-tuning each component to guarantee seamless operation and long-term performance.

Also including in our installation we provide remote and onsite support to further assist in any current or future issues with the system.

Milk Pasteurizer Process

In this project, we upgraded a milk pasteurizer system by replacing its aging MicroLogix PLC with a state-of-the-art CompactLogix L24 PLC. This upgrade involved integrating new 120VAC I/O modules, updating the PLC program to align with modern control standards, and performing a firmware upgrade to ensure optimal compatibility with the new hardware. Additionally, we replaced key system components to improve reliability and operational efficiency.

As part of our commitment to comprehensive service, we conducted a detailed annual preventative maintenance check on the control panel. This process included a thorough inspection of all wiring connections to identify and address any potential issues. By tightening all terminal connections, we mitigated the risk of loose wiring that could lead to downtime or operational failures, ensuring the system was robust and reliable for continued use.

To enhance the pasteurization process, we recalibrated the system using a precision-tuned PID loop to regulate the steamer and heat exchanger. This calibration was critical to maintaining the milk's temperature within 1/4 of a degree of its heat setpoint, ensuring a consistently high-quality product while optimizing energy efficiency. The recalibration not only improved the process's accuracy but also minimized variability, a key factor in achieving product consistency and meeting stringent industry standards.

This project highlights our ability to manage complex system upgrades, perform preventative maintenance, and optimize process performance. The results provided the client with a more reliable and efficient pasteurization system that supports their operational goals while maintaining the highest standards of quality.

IoT Systems

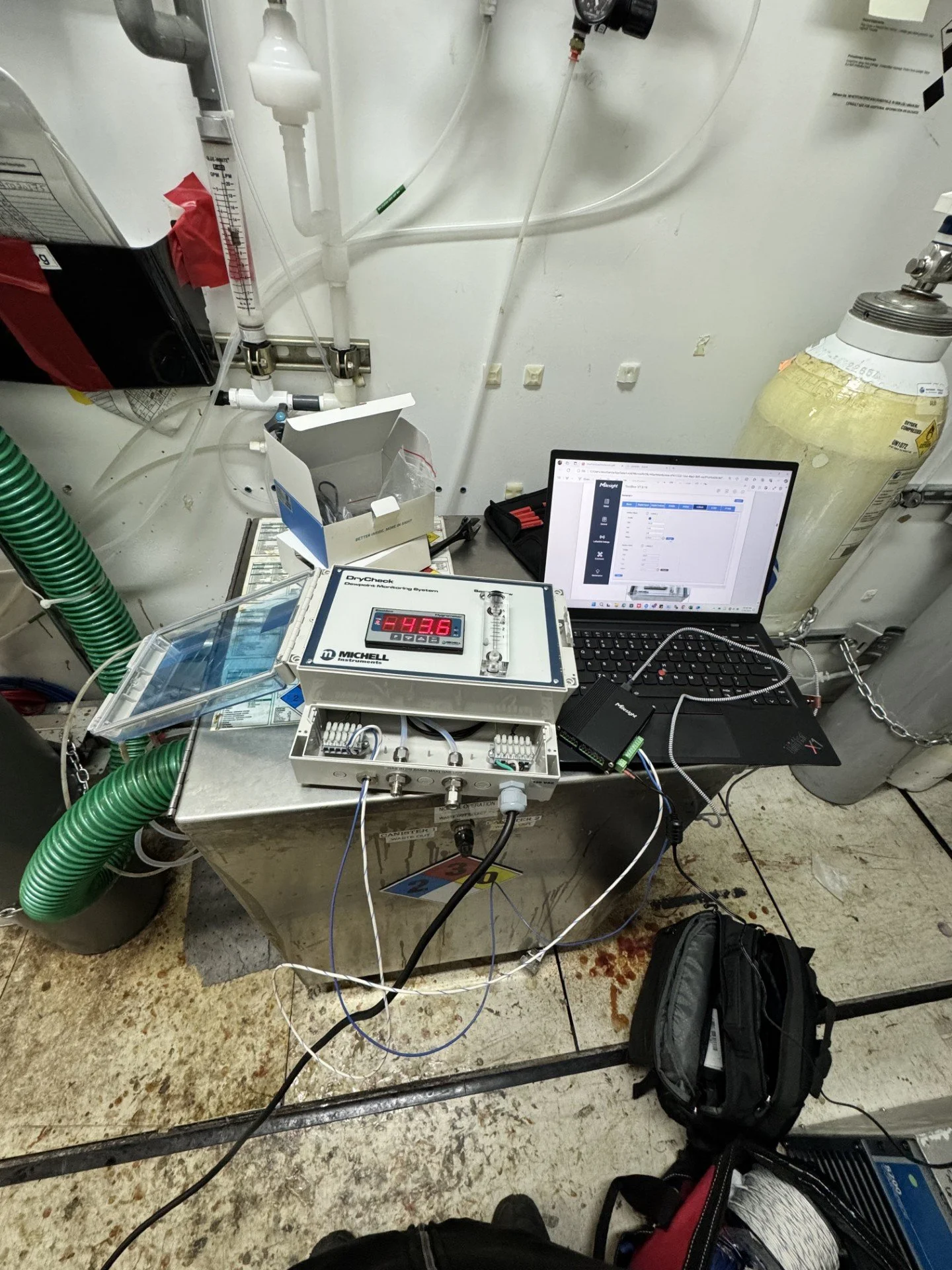

In Project Services we are working with IoT systems, assisting clients with integrating IoT sensors and consulting to determine the best applications for their unique needs. During these consultations, we thoroughly assess the client’s system, providing detailed reports on our findings and determining compatibility with various communication protocols, such as 4-20mA signals, Modbus, or Ethernet TCP/IP.

Our process begins with an on-site evaluation, where we perform a comprehensive overview of the client’s system to identify current capabilities and potential integration opportunities. Based on this analysis, we develop tailored solutions that meet their specific requirements. Once the solution is approved, our team handles the installation, programming, and commissioning of the IoT equipment, ensuring seamless integration with existing systems.

This approach allows us to deliver effective and efficient IoT solutions, enabling our clients to leverage advanced technologies to optimize their operations and achieve greater connectivity across their systems.